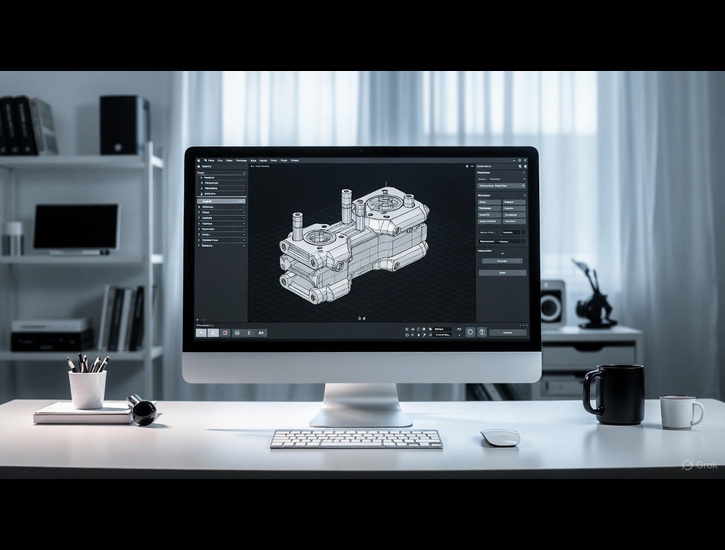

Design accuracy plays a critical role in successful manufacturing. Even minor design errors can lead to costly revisions, production delays, and wasted materials. To overcome these challenges, modern industries increasingly rely on advanced digital workflows that allow designs to be reviewed and refined before production begins. Among these workflows, 3D product modeling has become a powerful solution for improving precision and reducing risk.

By visualizing products in a digital environment, businesses gain better control over design quality, communication, and production readiness.

Ensuring Accuracy with 3D Product Modeling

Before manufacturing starts, every design detail must be validated. Traditional 2D drawings often fail to communicate complex structures, leaving room for interpretation errors. This gap can create misalignment between design intent and manufacturing execution.

3D Product Modeling provides a clearer understanding of form, scale, and structure. Teams can assess designs thoroughly, ensuring components fit correctly and meet functional requirements long before physical production begins.

How 3D Product Modeling Enhances Visual Clarity

Clear visualization is essential for accurate decision-making. Digital models allow designers and engineers to view products from multiple perspectives, revealing details that static drawings cannot show.

With 3D product modeling, stakeholders can identify design inconsistencies early, such as alignment issues or structural limitations. This clarity improves confidence in design approvals and helps avoid costly changes during manufacturing.

Improving Collaboration Across Design and Engineering Teams

Manufacturing projects often involve multiple teams working together. Without a shared visual reference, communication gaps can slow progress and introduce errors.

Visual Models as a Common Language

Digital models serve as a single source of truth for designers, engineers, and manufacturers. Teams can review the same visual data, provide feedback, and refine designs collaboratively. This shared understanding improves coordination and ensures that creative and technical goals remain aligned throughout the project lifecycle.

Reducing Manufacturing Risks Through Early Validation

One of the biggest advantages of digital workflows is the ability to validate designs early. Virtual reviews allow teams to test concepts, check assembly logic, and confirm functionality before production begins.

By identifying potential issues during the design phase, businesses reduce the risk of defects, rework, and production delays. Early validation supports smoother manufacturing and more predictable outcomes.

Supporting Efficient Prototyping and Production Planning

Physical prototyping can be time-consuming and expensive, especially when multiple revisions are required. Digital models help streamline this process by allowing teams to refine designs virtually before building physical samples.

Accurate visual models support better production planning, tooling decisions, and material selection. This preparation leads to fewer surprises during manufacturing and improves overall efficiency.

Ensuring Consistency and Quality Across Production

Consistency is essential for maintaining product quality at scale. Digital design assets provide manufacturers with precise references that help maintain uniformity across production runs.

By relying on detailed visual data, production teams can ensure that each unit meets the same specifications and quality standards. This consistency is especially valuable in industrial and large-scale manufacturing environments.

Driving Innovation with 3D Product Modeling

Innovation often requires experimentation and iteration. 3D Product Modeling enables teams to explore design variations quickly without committing to physical production.

This flexibility encourages creative problem-solving while maintaining accuracy and control. Businesses can refine ideas, test alternatives, and optimize designs with minimal risk and cost.

Conclusion

Accurate design is the foundation of successful manufacturing. By adopting advanced digital workflows, businesses can reduce errors, improve collaboration, and validate designs with confidence. 3D product modeling empowers teams to move from concept to production more efficiently while maintaining high standards of quality and precision.

As industries continue to evolve, digital visualization will remain a key driver of smarter, faster, and more reliable product development.

Call to Action

Looking to improve design accuracy and reduce production risks? Partner with a professional 3D Rendering Studio that understands industrial workflows and precision-driven design. Discover how our visualization expertise can help bring your product ideas to life with clarity and confidence.

Frequently Asked Questions (FAQ)

What is this process used for before manufacturing?

It is used to create detailed digital representations that allow teams to review structure, dimensions, and functionality before production begins.

How does this approach help reduce manufacturing errors?

Early visual reviews and virtual validation help identify issues before materials are committed, reducing rework and production delays.

Can digital models support marketing and presentations?

Yes, realistic visuals are often used for client presentations, investor pitches, and early product promotion before physical samples exist.

Is this suitable for complex industrial products?

Absolutely. Advanced visualization techniques simplify complex assemblies and improve communication across technical teams.

Who benefits most from this workflow?

Manufacturers, engineers, and product designers benefit by improving collaboration, efficiency, and production readiness.